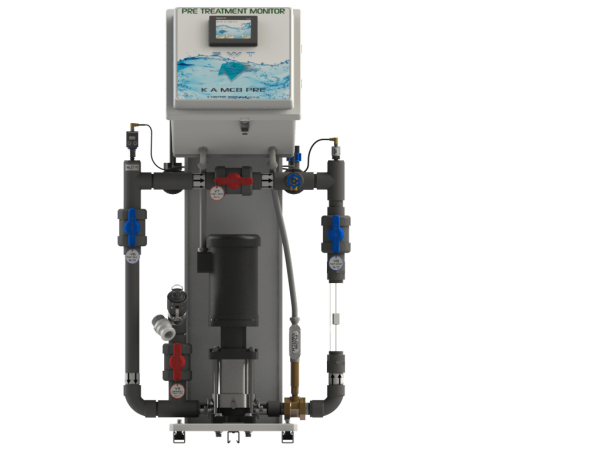

Description

The (K-A-MCB-PRE) Municipal Boost with Pre-Treatment Monitoring System is designed to be the central nervous system of the pre-treatment components of a water purification system. The system monitors pressures, temperatures, flows, automated valve positions, and pre-treatment timer head cycles. It also controls the pre-treatment Municipal Booster System, the RO interlock and the pre-treatment automated valves allowing for both monitor driven safety and active testing sequences. It is the central interactive hub for all alarms pre-treatment, and the SWT RO. These alarms are relayed from the control box to the Remote Monitor (Smart Nurses Station).

The K-A-MCB-PRE Municipal Boost w/Pre-Treatment Monitoring System incorporates the VFD Municipal Booster System utilizes a Variable Frequency Drive motor controller in lieu of a contactor and thermal overload. The system is also equipped with a pressure transducer which senses the pressure on the outlet/discharge side of the pump which will maintain the pressure programed into the controller.

Once installed and calibrated, the system will adjust and maintain the preset pressure required for adequately running the RO system and the regeneration cycles of the media tanks. The pressure sensor continuously transmits an electronic signal to the VFD motor controller, which then accelerates or decelerates the pump in an attempt to maintain the preset pressure. This speed adjustment is accomplished by varying the frequency of the power going to the motor on the pump, which in turn controls the speed (RPM revolutions per minute) at which the motor, and therefore the pump, turns. The motor/pump RPM controls the amount of pressure and flow the pump produces.

This allows the pump to operate when the R.O. turns on, or when a pre-treatment component (such as a media tank) goes into backwash and/or regeneration. This tight control all but eliminates pressure spikes when the R.O. turns off, and also prolongs the life of the Municipal Boost pump and motor.

Included is voice call leak detection that will shut off the incoming water and dial programed telephone numbers with a message if leak is detected. Also standard is Cold Water Bypass with Auto Cool, E.B.C.T Monitoring, Event Logging with CSV File Data Transfer Port (USB), Pressure Holding Test, pH Monitoring with Audible Alarm, and a Chlorine Testing Timer with Shift Interval, Auto RO On, and Sample Port Flush.